Rubber Washers - Sealing Washers - Rubber Spacer Can Be Fun For Anyone

Beer Line Rubber Washer - Set of 6kegworks.com · In stock

.318 ID Black Rubber Washer - Fastenal Things To Know Before You Get This

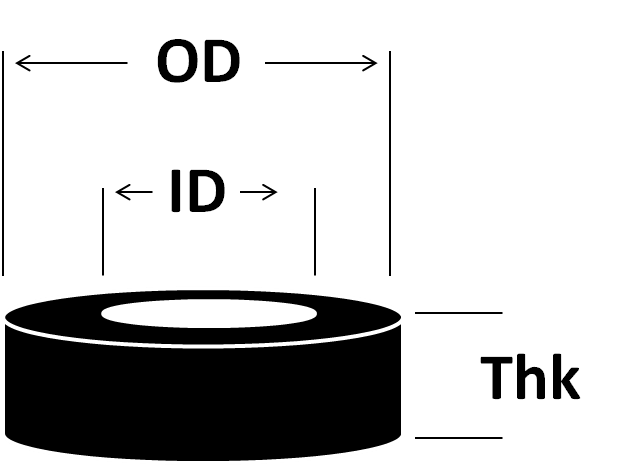

Foam washers may be used to help fulfill these needs, but they can weaken with time. A rubber washer, being stronger and less vulnerable to damage, will last longer, especially if the fasteners around the washer are frequently tightened and loosened. A rubber washer has the possible to create a seal which can be utilized to avoid fluid or air from leaking.

Non perfect applications for rubber washer would be not to use with destructive liquids, and they may interact adversely with some other kinds of liquids. They also need to not be put in extreme heat as melting can occur. In addition, rubber washers exposed to distinctions in temperature with the combination of changes in humidity, should be replaced occasionally.

Grommets are normally flared or collared on each side to keep them in location, and are typically made from metal, plastic, or rubber. Superior Washer & Gasket Corp. might be utilized to prevent tearing or abrasion of the pierced product, to cover sharp edges of the piercing, or both. Grommets made of rubber or other flexible materials are also used to minimise the transmission of vibration.

Excitement About Neoprene Rubber Washer - Rubberfeetwarehouse

A gasket is a mechanical seal which fills the space in between two or more breeding surfaces, normally to avoid leakage from or into the joined objects while under compression. All of our seals, gaskets and extruded profiles are cut and manufactured utilizing computerised presses, CNC cutting devices and cutting-edge water jet innovation.

Danco 61808B Rubber Washer 1-1/2 By 3 hardwareandtools.com · In stock

We provide water jet cutting, this is where a high pressure jet of water is directed from a nozzle to cutting through the product. Water jets are general utilized to cut through softer product such as rubber and foam nevertheless abrasive product can be contributed to the water such as garnet and aluminium oxide to cut through stainless-steel or brass without tarnishing it.

Among our makers is abrasive assisted enabling it to cut through plastics, aluminium, glass and marble. Parts are cut from highly light-weight foams approximately solid rubbers and plastics with the help of abrasive cutting. Double density products with facings and self-adhesive backings are laminated in-house to satisfy our consumer's item needs.